SILICON ENERGY FIBER

What Is Silicon Energy Fiber?

Silicon is found in many dioxide forms and uncountable variations from the natural silicates.

The silicon is much more abundant than any other element, apart from the oxygen. It constitutes 27.72% of the solid Earth’s crust, while the oxygen constitutes 46.6%, and the next element after silicon, aluminum is 8.13%. Controversy about silicon’s character dates to its discovery. It was first prepared and characterized in pure form in 1823. In 1808, it was given the name silicium (from Latin: silex, hard stone or flint), with an -ium word-ending to suggest a metal, a name which the element retains in several languages. The present English name was first suggested in 1817 to conform to the physically similar elements, carbon and boron.

Details

Sri-Lanka has abundant mineral ore on the whole island and the crystal produced is the most pure with silicon content up to 99.5% ~ 99.7%. Silicon is the basic raw materials of Hi-Tech and semi-conductive industry.

The earthquake and tsunami which occurred on Dec. 26, 2004 devastated wide areas of South Asia. It affected 11 countries and killed more than 225,000 and displaced 1.2 million people. Ski Lanka was one of the affected country and many people became homeless.

Tzu Chi volunteers from Taiwan rushed to the affected area and offered free clinics, distributed essential supplies, and helped the nation to rebuild. Mr. Ko the chairman of Ecomax Textile Co., Ltd & Tzu Chi volunteer recalled as if seeing the whole city was bombed and destroyed and looked like a war zone. Mr. Ko picked a silicon stone from the disaster area and thought how he could take advantage of this stone and thereby help to rebuild Sri Lanka.

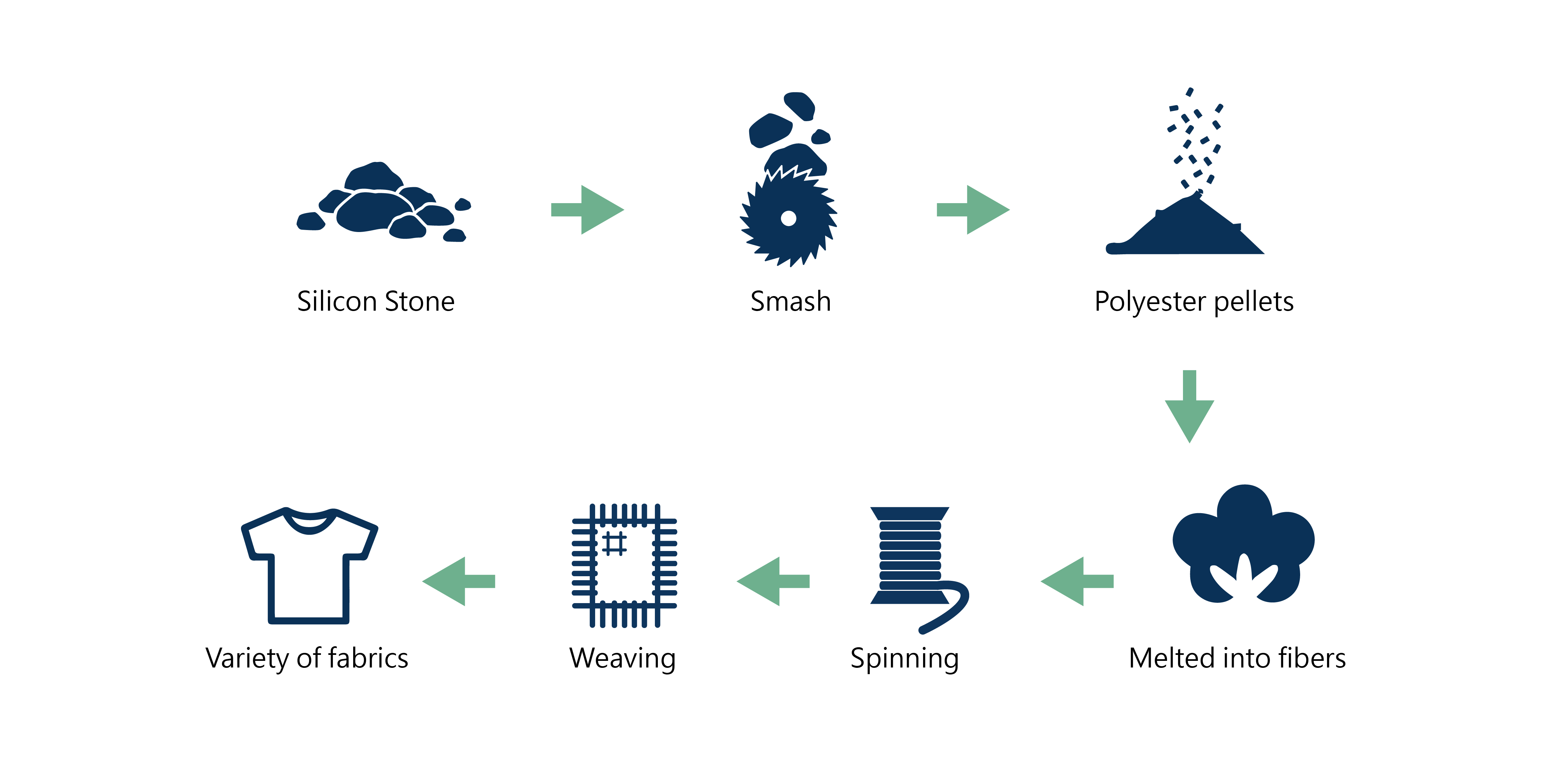

Based on this idea, Ecomax imported silicon from Sri Lanka and developed to utilize this silicon material. The silicon was grinded and filtered into nano-sized particles, and then added into recycled PET fiber.

For recycled polyester, the nano particles were doped evenly when the yarn was extruded. The fibers are then spun into yarn. As the silicon powder is equally diffused into the yarn structure and are not coating on the surface, therefore any method of washing will not influence its function. It has excellent water-resistance and the best choice for warm textiles.

Procedure

Features

- The far infrared ray preserves heat and helps blood circulation and keeps us health. With thermal effect, it’s able to preserve heat for temperature maintenance and strengthen the blood circulation thus promoting metabolism.

- The silicon can release anion (air vitamin) and improve human energy. According to Pierce J. Howard, PhD, it increases the flow of oxygen to the brain, resulting in higher alertness and more mental energy. They also may protect against germs in the air. Neutralize body cation (positive ion) makes you tireless & improve blood circulation and purifies blood.

- The intensity of negative ion (anion) released will effectively suppress the survival and multiplication of bacterial and viruses. The anions present in the air possess an electrode which easily gets attached to the surface of bacteria or viruses. This then produce a low electric current that helps to eliminate them and suppresses further multiplication, thus achieving the effects of eradicating bacteria and sterilization.current that helps to eliminate them and suppresses further multiplication, thus achieving the effects of eradicating bacteria and sterilization.